Make a Guitar Template

To make a guitar template isn't rocket science. I use a system where the outline and cavities are on separate physical templates. That way I can mix and match body shapes with different pickups simply by changing the combination of templates. I know I didn't invent this method, I think it's a fairly common approach.

For Neck pocket templates I use an entirely unique method that results in a perfect hand-in-glove fit every time. The method is described in a separate page (follow the link above).

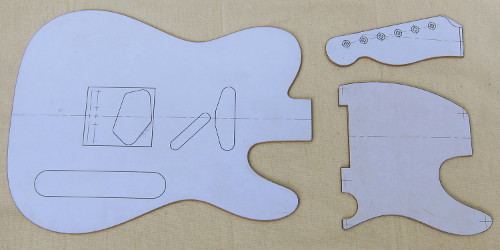

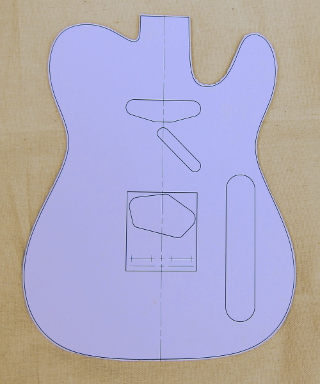

Examples of guitar templates. What's missing in the picture are cavity and neck templates.

Examples of guitar templates. What's missing in the picture are cavity and neck templates.The point of using a template is to accurately transfer the shape from a piece of paper to the lumber that will become the guitar body. Once the template is made, the shape is transferred to the body blank using a router with a pattern bit.

Make a Guitar Template - the Nuts & Bolts

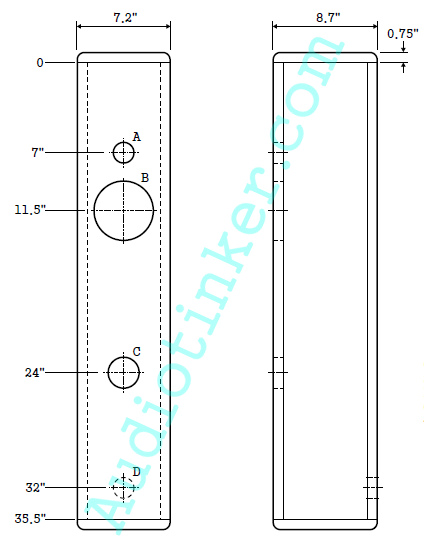

Most of my templates start out as a drawing on 2D CAD. For small templates, like pickguards, pickups and cavities, I usually print them out on office paper, if at all. Some of my cavity templates have been made on the fly without a drawing, so YMMV.

Guitar bodies are too large to fit on regular office paper, so those has to be printed on a large format printer. I usually go to Kinko's or the UPS store locally. Office supply stores, such as Office Depot and Staples often have the capability as well. I bring my files over on a thumb drive.

Each body or pickguard print-out is cut out from the paper sheet and glued onto 3/16" hardboard. I'm not particularly neat when I cut them out. I try and leave about 1/4" of paper all around the perimeter and don't follow exactly. For instance, the cutaways are typically skipped over and left solid.

For cavities, I just glue down the paper on the hardboard.

The glue I use is 3M "Super 77" spray adhesive. It works great, but is stinky and flammable. I use it outside whenever weather permits.

The hardboard is then trimmed closely (1/16" or closer) to the contour with a jigsaw, smoothed with a 4-in-1 rasp or file, and finished with sandpaper right up to the line, with one exception...Lately I have been making my templates slightly wider at the heel, just so I know positively that there is material to trim back flush with the neck. So I simply don't go up to the line in that area, but leave maybe 1/32".

It bears saying that a smooth edge on a body or pickguard template will pay dividends in less work necessary to finish sanding the body later.

Once the template is done I add a couple of countersunk holes where the pickups will eventually go on the guitar. I use these holes to attach the template to the body blank. Some people use double-sided tape. I have experienced tape pulling fiber from the wood and also having the template come loose while routing. Both experiences led me to my current method.

Northern White Cedar guitar body blank with rough edge cut with a jigsaw Northern White Cedar guitar body blank with rough edge cut with a jigsaw |

The same guitar body edge trimmed with a router and a template The same guitar body edge trimmed with a router and a template |

Before taking the router to the wood, the shape needs to be roughed in using a jigsaw or bandsaw. Lay the finished template on the body blank and mark the perimeter with a pencil.

How close to cut with the saw is a game of chicken. The closer the better in terms of bit wear, tear-out in the wood and general router stability etc. On the other hand you don't want to risk crossing the line and ruining the body blank. I typically aim for 1/16" in most cases. Some wood species are more forgiving than others as well.

Contour Templates

|

The first type is simply the body, pick-guard or peghead outline laid out separately on a sheet of paper. All my templates are generated from CAD and saved as pdf files, with the intention to be printed out on an accurate printer. Smaller templates, like headstocks and pickguards can be printed out on an office laser printer or inkjet. |

A Mini Telecaster Template A Mini Telecaster Template |

Guitar Cavity Router Template

|

The second type of templates are for the different cavities on physically separate from the outline templates and are of the different cavities on a guitar body, such as control and pickup cavities. These templates can be ugly as sin, but gets the job done. A note of caution when using a template for the first time: Test it on a scrap piece and dry fit the hardware or pickup or whatever. It gives you a chance to make corrections before cutting into your precious material. |

Bridge Pickup Template on a Telecaster Bridge Pickup Template on a Telecaster |

Neck Pocket Templates

|

With so many after-market bolt-on necks out there, one would hope they are all interchangeable. Unfortunately, at least at my budget level, that is rarely the case. For that reason I have developed a method of making neck pocket templates that I think is pretty unique. The result is a perfect fit every time. I essentially make a molded router template for each neck I use. It's actually really fast, cheap and easy. There is a separate page describing how to make a neck pocket template if you follow the link. |

Neck pocket template in use Neck pocket template in use |

Templates in Use

The following pages show different guitar templates in use:

- Guitar Body

- Headstock

- Pickguard

- Neck Pocket

- Pickup Cavity

Downloadable Guitar Templates

Templates will be available for download once each guitar project is finished.

Recent Articles

-

Speaker Plans

Feb 04, 18 05:23 PM

Speaker plans for download - free pdfs for DIY builders and tire kickers